Design and Synthesis of Integrated Nanocatalysts

|

|

|

|

|

Related

Research Thrusts

|

|

• Design and synthesis of nanomaterials for energy and

sustainability

• Development and integration of novel catalytic

materials

• Synthetic architecture of advanced functional

materials

|

|

Program

|

|

In recent years, “nanocatalysts” has become a term often

used by the materials chemistry and catalysis community

[1]. By controlling particle composition, structure,

shape, and dimension, researchers can move into the next

phase of catalyst development if they are able to bridge

old and new technologies. In this regard, one way seems

to be to integrate active catalytic components with

boundary-defined supports, which therefore retains the

essence of traditional “catalyst-plus-support”

configuration. The resultant catalysts have advantages

for material engineering that often involves high level

designs and integrations in their fabrication. Besides

this, the active components in this new type of

catalysts are in nanoscale and are easy to integrate

into supporting material phases. For these reasons, we

name such catalytic devices as integrated nanocatalysts

(INCs) [1]. In our group, we carry out this type of

materials research and develop new synthetic strategies

and architectural designs for INCs with increasing

compositional and structural complexities in order to

meet new challenges of heterogeneous catalysis in energy

and sustainability applcations.

|

|

Background

|

|

Integrated nanocatalysts (INCs) with multicomponent and

hierarchically complex structures have recently drawn

extensive research attention in terms of their

fundamental sciences and industrial applications, and

many innovative strategies have been established [1]. In

pursuing this type of research, we are developing the

state-of-the-art of INCs with different porous materials

for catalyst technology and heterogeneous catalysis. In

our research, we synthesize different nanoparticles or

clusters (namely, metal, metal oxide, and hybrid

nanoparticles) that are catalytically active in INCs

[2]. Combining such active components with various

porous materials provides us a huge array of

architectural designs for INCs that can be used in

chemical reactions. In choosing host materials for INCs,

we particularly focus on shape-controlled mesoporous

siliceous materials (e.g., silica and metal silicates)

and microporous metal-organic frameworks (MOFs), since

they represent the two important classes of porous

materials known today. In our research program,

therefore, we develop INCs which comprise these

mesoporous and microporous solids and active catalytic

components. A special emphasis is placed on their roles

as supports, encapsulating shells and metal sources for

targeted applications of energy and sustainability.

|

|

Methodologies

|

|

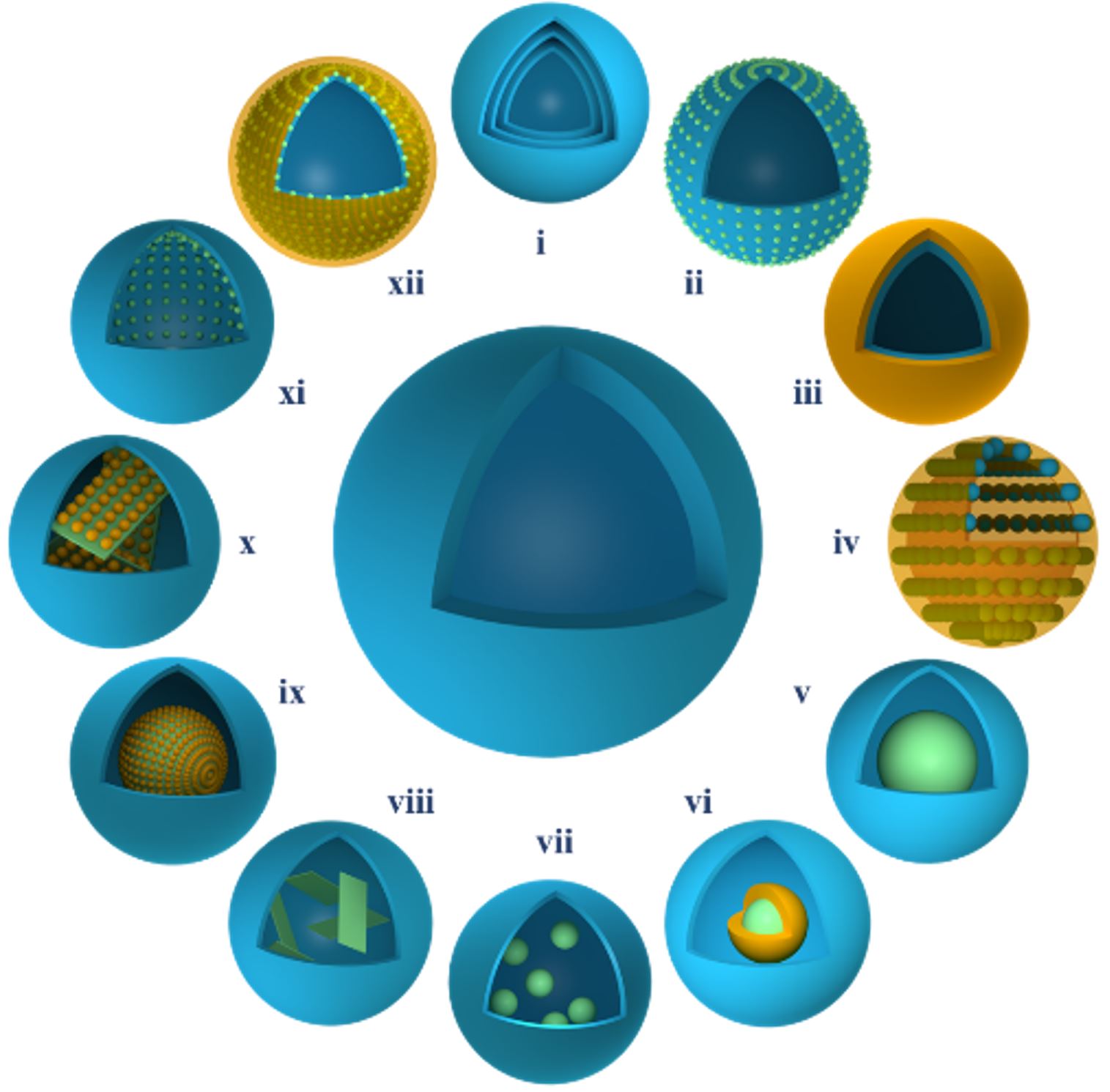

Basically, two types of materials are used in

construction of these catalytic devices: active catalyst

components and their supporting carriers [3-8]. In

preparing INCs, various synthetic methods have been

developed in recent years [5, 6]. Normally, the active

components are synthesized into monodisperse

nanoparticles through wet chemical routes. On the other

hand, the catalyst carriers or hosts are often prepared

as hollow or porous materials with desired

shape-controls [3, 4]. In general, integration of the

above two types of catalytic materials can be achieved

in a step-by-step manner [7-9]. Both top-down

(e.g., dissolution and regrowth) and bottom-up

(e.g., self-assembly and deposition) strategies have

been employed in the synthetic architecture of INCs

(Figure 1) [5, 6].

|

|

Examples of

Research Activities

|

|

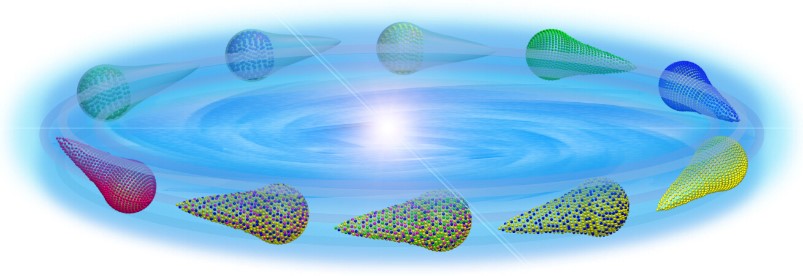

In heterogeneous catalysis, structure and shape of solid

catalysts play an important role in their interactions

with reaction fluids and thus catalytic performance. For

instance, intrinsic nanostructure of catalysts and

related packing in fixed bed reactors will determine the

retention time of gaseous reactants and reaction

intermediates on catalyst surfaces, which in turn

enhances the conversion and selectivity if more

travelling routes and longer travelling paths for

reactants can be created within a catalyst bed, as

reported in our recent investigation on gas-phase

hydrogenation of carbon dioxide [3]. Additionally,

geometric shape of particulate catalysts also impose

significant impacts on their performance, because an

optimal configuration of catalyst can promote transport

processes and thus increase catalytic activity in

fluid-related reactions or environments (Figure 2) [4].

In this regard, a streamline body may represent a

superior geometry since it experiences minimum fluid

resistance. In this latter example, we developed a new

class of integrated nanocatalysts with a streamline body

and tunable chemical compositions. Advantages of these

shape-controlled catalysts were further demonstrated

with some model reactions such as liquid-phase alcohol

oxidation, olefin hydrogenation, and Suzuki-Miyaura

coupling, in comparison with their commonly used

counterparts [4].

|

|

Future

Direction

|

|

Departing from their conventional counterparts, the

state-of-the-art catalysts for heterogeneous catalysis

can be designed and prepared in a controllable fashion

owing to rapid development of nanoscience and

nanotechnology as well as the maturing chemistry of

materials over the past two decades. It is anticipated

that compositional and structural requirements of such

catalysts can be met with a higher level of

sophistication and precision but at a lower cost. As

most of commercial catalysts use expensive metal

elements (such as noble metals), INCs represent a future

form of catalysts to boost atom economy of these

precious metals. However, realization of this

paradigmatic shift for modern catalyst manufacturing

would still require collective efforts from the research

community. We envision that the synthetic architecture

of nanomaterials will become an important field in

future development of state-of-the-art catalytic

materials. We also believe that further integrations of

a single type or multiple types of INCs could lead to

even more powerful “supracatalysts”, achieving

industrial scale applications [1].

|

|

|

|

Figure 1. Design and synthesis of 12

representative reactor-like integrated nanocatalysts

[6].

|

Figure 2. Streamline-shaped INCs made from

noble metals/organic-inorganic hybrids [4].

|

|

References

|

|

[1] H.C. Zeng, Integrated Nanocatalysts, Acc. Chem. Res.

46, 226-235 (2013).

[2] G.W. Zhan, H.C. Zeng, Integrated Nanocatalysts with

Mesoporous Silica/Silicate and Microporous MOF

Materials, Coord. Chem. Rev. 320-321, 181-192 (2016).

[3] G.W. Zhan and H.C. Zeng, ZIF-67 Derived Nanoreactors

for Controlling Product Selectivity in CO2

Hydrogenation, ACS Catalysis 7, 7509-7519 (2017).

[4] G. Zhan, H.C. Zeng, Smart Nanocatalysts with

Streamline Shapes, ACS Cent. Sci. 3, 794-799 (2017).

[5] G.W. Zhan, P. Li and H.C. Zeng, Architectural

Designs and Synthetic Strategies of Advanced

Nanocatalysts, Adv. Mater. 30, 1802094 (2018).

[6] B.W. Li and H.C. Zeng, Architecture and Preparation

of Hollow Catalytic Devices, Adv. Mater. 30, 1801104

(2018).

[7] G.W. Zhan and H.C. Zeng, Hydrogen Spillover through

Matryoshka-Type (ZIFs@)n-1ZIFs Nanocubes, Nat. Commun.

9, 3778 (2018).

[8] Y.C. Tan and H.C. Zeng, Defect Creation in HKUST-1

via Molecular Imprinting: Attaining Anionic Framework

Property and Mesoporosity for Cation Exchange

Applications, Adv. Funct. Mater. 27, 1703765-73 (2017).

[9] Y.C. Tan and H.C. Zeng, Lewis Basicity Generated by

Localised Charge Imbalance in Noble Metal

Nanoparticle-Embedded Defective Metal–Organic

Frameworks, Nat. Commun. 9, 4236 (2018). |

|